Levison Enterprises Difference – Trusted Electronics Manufacturer

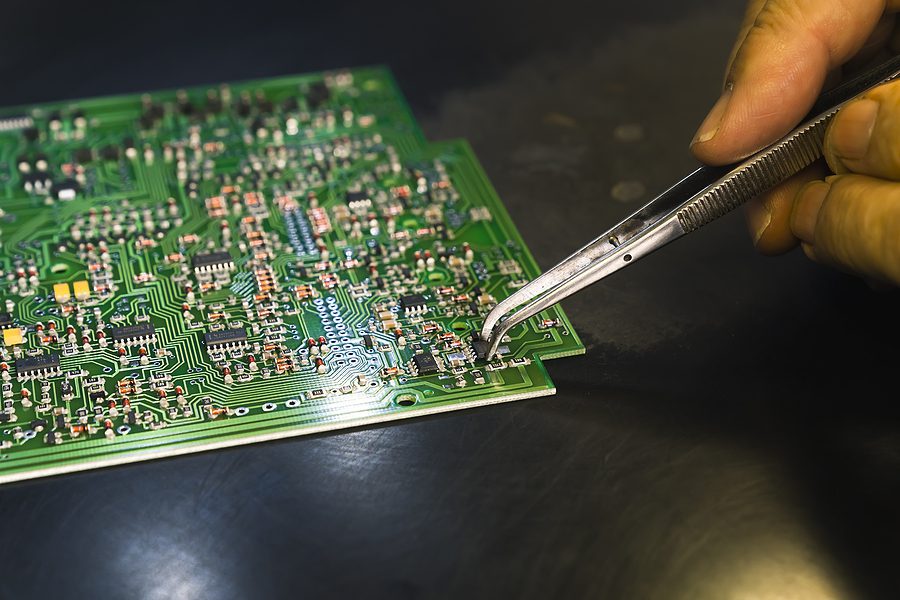

To truly excel at something requires you to immerse yourself in your work. Levison Enterprises has spent countless hours mastering electronic manufacturing design and production processes.

Today’s consumers demand more than ever before and expect companies, even small and mid-sized, to turn products around quickly. A trusted ECM partner can help you achieve your goals while delivering quality products that keep customers happy and loyal.

Below is an inside look at what sets Levison Enterprises apart.

Turnkey Shop

A turnkey facility is always an excellent choice for an ECM partnership. Turnkey facilities can complete your entire project in-house with the experts, experience, and equipment needed to complete any project successfully. A turnkey shop means everything is done under one roof, so nothing is subcontracted.

Several benefits of using a turnkey shop like Levison Enterprises, includes having a vetted and trusted supply chain. This means we’ll always know the availability of components and be able to accurately forecast the risk of parts becoming obsolete, allowing us to stock up as soon as we determine a part may quickly become hard to find.

A turnkey ECM proactive in parts obsolescence has an existing trusted network of vetted suppliers to turn to when a part is in danger of becoming hard to find. This enables the engineering team adequate time to determine if there is a substitute for the part or an appropriate aftermarket source.

Certifications

Certifications are essential. When your ECM has the proper certifications, it shows they’re dedicated to meeting industry regulations and standards and are committed to continuous improvement. In some industries, certifications are required to produce a product that meets the regulations and that cannot be ignored. Before beginning your next project, make sure your ECM has the proper certifications for the job.

We’ve invested time and resources at Levison Enterprises to obtain and maintain our quality certifications. We’ve adopted stringent quality process systems throughout our design and manufacturing operations. Each team member takes pride in knowing they’ve played a part in our process metrics. We conduct internal and external reviews and audits as we believe that a strong focus on reliability leads to customer satisfaction.

In addition to certifications, Levison Enterprises has vast multi-Industry knowledge and experience, including accurate component forecasting. We work with you versus for you. We have the industry knowledge you don’t. We can help you streamline your plans for a better product. We work hard for your success.

Design Services

You may have done the design work already, but choosing an ECM like Levison Enterprises will help your product succeed. You can come to us with an idea, and we can help you bring your product to market. A turnkey facility with design services is more essential than most companies realize.

Engineers on Staff

At Levison Enterprises, we proudly supply every project with a team of in-house engineering experts. Our team will look over your existing design and make suggestions that increase your project’s reliability, efficiency, cost-effectiveness, and manufacturability.

Redesign and Reverse Engineering

At Levison, we can redesign and reverse-engineer your product. When a legacy device or project goes down, the original PCB or Gerber files might not be available. Reverse engineering services at Levison Enterprises are the solution to meld the old technology with the new and aid in component obsolescence becoming less of a problem.

Component obsolescence and the rapid advancement of technology are among the biggest challenges for electronic device manufacturers. Widely used parts can’t be manufactured quickly enough or may be unavailable. Designers and manufacturers must find a way around component obsolescence, and seeking alternative parts is typically the solution. However, completely replacing a component is not always cost-effective. The answer is retrofitting or reverse engineering, allowing older technology to adapt to newer specifications with widely available parts. Retrofitting and reverse engineering can help bring older technology up to date, help that technology meet new performance standards, and streamline older product designs to current configurations.

DFM Analysis

Levison Enterprises is a full-service, turnkey ECM offering a wealth of services to our clients. We understand the needs facing electronic manufacturers today in a competitive and fast-paced market, and Design for Manufacturing (DFM) analysis is one of our many areas of expertise.

Proper DFM analysis requires intelligent design, rigorous testing, and access to the latest prototyping technologies and analytical tools. Levison Enterprises has more than 100 years of combined personnel experience in electronic technology and testing protocols.

A DFM analysis aims to find a product design involving the least amount of complexity in manufacturing the different components. Modern electronic devices are complex, so a DFM analysis can find ways to reduce excessive materials spending and produce more streamlined products. While Design for Assembly analysis simply aims to cut product assembly costs, DFM analysis aims to reduce the overall costs for producing all the parts of a product or assembly.

Prototype Service

Levison Enterprises’ rapid electronic prototyping helps our clients create cost-effective designs with minimal chance of needing to redesign or redo, helping impress your potential investors with innovative ideas.

Prototyping is a necessary stage of the manufacturing process. After the design and before production, there is a window where you, together with your electronic manufacturer, can take a thorough look at the design and components of your project. A prototype will allow your project to move from the theoretical to the concrete stage, and this is your opportunity to identify and address potential problems before manufacturing.

Rapid prototyping can give you the information you need in only a few days, and this quick turnaround will keep your project moving forward. There is no disadvantage to going through the prototyping stage to ensure you have the best product possible. Here at Levison Enterprises, we highly recommend this process for every build.

If you’re looking for an ECM partner who can help you build a successful device, contact Levison Enterprises for a quote on your next project.

Start Your Quote Now!