Supply Chain Security in Defense Electronic Manufacturing

When national security is at stake, defense electronic manufacturing partners are required to meet strict standards and regulations. Supply chain issues and component shortages have presented many challenges for product traceability. Ultimately, the best way to ensure supply chain security is to work with a certified turnkey, electronic contract manufacturer. One that keeps the project here in the USA with a strong network of vetted suppliers.

The Importance of Supply Chain Security

Defense manufacturing relies on security at every stage in the process. No matter how big or small the component, national security is at risk during the design and manufacturing process. Regulations are there to ensure that security can be balanced with effective manufacturing and component sourcing. Supply chain shortages are still a big problem in every industry, but in the defense industry, the solutions need to be compliant and secure to protect the process from external threats.

Threats That Challenge Supply Chain Security

There are several threats that are present in supply chain security. The first threat has to do with cybersecurity. The more digital and connected electronic components become, the more risk they face. Hackers and cybercriminals target defense manufacturing to gain access to sensitive information or disrupt operations. It is critical that anyone dealing with supply chain sourcing in the defense industry is making sure to use best practices in cybersecurity.

Another challenge is the complexity and globalization of electronic manufacturing. The bigger the pool gets, the more threats to potentially attack and derail a defense manufacturing project. Every phase of a project is another opportunity for a security threat, and a reliance on foreign suppliers raises additional concerns. While it is not always possible to stay entirely domestic in the supply chain, focusing on domestic manufacturing and expanding the supplier base to include more trusted and vetted suppliers can help address this problem.

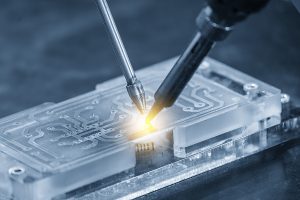

Electronic chips can always be a risk. The more complex they get, the bigger the opportunity to hide malicious functions. It is important that defense electronic manufacturers understand what to look for in each component and what to do if they suspect a risk.

Preventing Counterfeit Components

When component shortages are a concern, there is a risk of counterfeit components. Counterfeit parts may not only be “fake”, but are often components that have been harvested from discarded systems, relabeled, and sold as new. Suppliers who have not been vetted and are quick to provide components that are facing shortages may be offering counterfeit components. These components pose a serious risk for all electronic manufacturing, but in defense devices, the problems are more serious. Not only are counterfeit components likely to fail and pose a potential safety hazard, but if a product is determined to be out of compliance due to a counterfeit component, there are repercussions that can be very costly.

To mitigate this risk, it is essential that components are only sourced from trusted vendors and vetted suppliers. Any supplier providing components for defense electronic manufacturing should have a proven track record of reliability and transparent sourcing that ensure product traceability.

Ensuring Product Traceability

Product traceability is a key piece of regulatory compliance in defense electronic manufacturing. Every component needs to be tracked and documented throughout the process, from sourcing each component through to the final delivery to the customer. When prioritizing supply chain security, there are some things an ECM can do to improve product traceability. This can include traceability software, RFID technology, digital product passports, and supplier traceability controls. Product traceability relies on collaboration and documentation from all partners in the manufacturing process. Training everyone involved in the process is one of the best ways to ensure everyone is always on the same page and no components are able to slip through the cracks.

Having a Regulatory Compliance Framework is Key

Prepare before the process. When the framework is in place, issues such as supply chain shortages, counterfeit component mitigation, and cybersecurity are far easier to deal with, as they will already have plans in place that everyone on the project will be familiar with. Processes can be streamlined, and a system in place for checks and balances will make sure that the entire process stays compliant and secure. When a failure in compliance has such severe consequences, having a culture that is founded on planning, integrity, and continuous improvement will ensure that all regulatory requirements are not simply met, but exceeded.

Finding an ECM Committed to Supply Chain Security for Defense Electronic Manufacturing

The right ECM is the most important factor in your device’s compliance and security. Any ECM experienced in defense manufacturing will be very familiar with the regulations needed. Finding a domestic turnkey ECM with a strong network of vetted suppliers is important. Every component will be tracked throughout the product lifecycle and security measures will already be built into the process.

Levison Enterprises is committed to the unique needs of defense electronic manufacturing. We have a strong network of vetted suppliers and safeguards in place to protect against counterfeit components.

Maintaining supply chain security requires careful attention to every phase of the process, from sourcing components to final delivery. With growing cybersecurity threats, the risk of counterfeit components, and the complexity of global supply chains, it’s important to work with a trusted, certified turnkey ECM. Levison Enterprises offers the expertise and infrastructure you need to meet your regulatory requirements. Contact us today for a quote on your next device.

Start Your Quote Now!