Comparing and Ultimately Choosing an Electronic Manufacturer

When you are searching for an electronic manufacturer and comparing different companies, the lowest price should not necessarily be your biggest consideration. In fact, some overseas companies may offer what appears to be low cost outsourcing, but their lack of benefits makes choosing a domestic PCB manufacturer much more appealing. When comparing and choosing an ECM, there are several key aspects to look out for.

Does the ECM Have the Expertise?

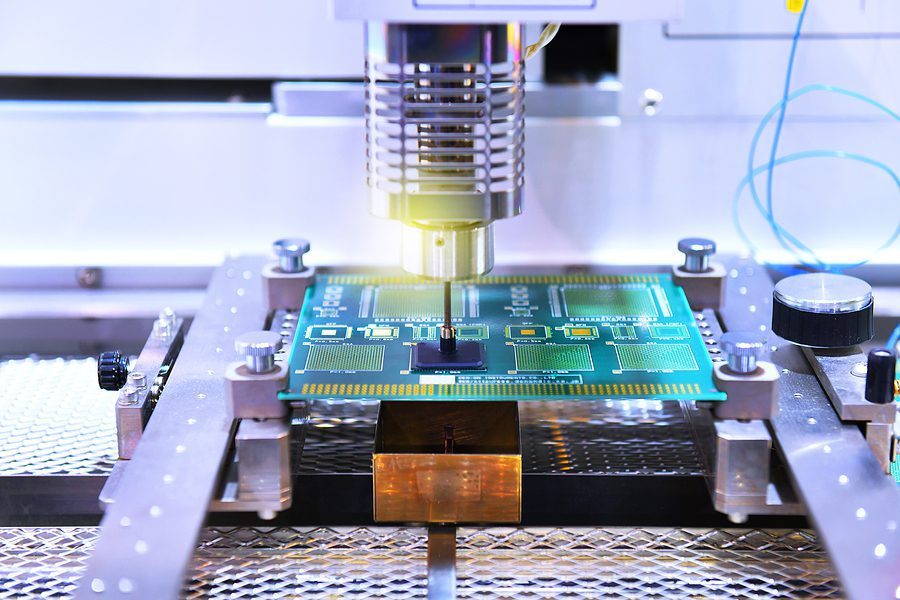

Look at the standards your ECM holds themselves too and the projects they have worked on. The ECM you choose to partner with should have a proven record of producing excellent work, particularly in highly regulated industries. A turnkey facility should have experience and expertise in all aspects of PCB manufacturing, from design, to prototyping, to testing, to assembly, to delivery.

Does the ECM Have the Right Industry Experience?

Having experience is one thing, but you need to ensure that your ECM partner has the right industry experience for your project. In highly regulated industries, such as medical, defense, and aerospace, having a partner with the right experience and credentials is crucial to meeting the precise specifications and rigorous demands.

Does the ECM Provide Design Services?

A turnkey facility can handle your project from design through delivery. Although you may have your design in place, choosing an ECM with design services increases the likelihood that your design will be vetted by experienced engineers who can tweak the design if any issues show up during the prototyping process. Without those services, any potential issues that arise during prototyping can cause significant delays once you are in the production phase of your project.

Does the ECM Have Onsite Engineering Services to Optimize and Streamline a Design?

Having onsite engineers to optimize and streamline your design can save you both time and money in the long run. Engineers understand how to take your product from design through production with success and can make the necessary adjustments to optimize and streamline your design without sacrificing any quality or functionality. Onsite engineers can ensure that the component is designed with manufacturing in mind.

Does the ECM Have a Vetted Supply Chain and a Counterfeit Parts Avoidance Plan in Place?

A vetted supply chain is crucial to manufacturing your components without delay. An ECM with a vetted supply chain will be able to get the right parts without delay. This vetted supply chain will not only help with parts obsolescence, but will help avoid counterfeit parts. Counterfeit parts are not held to the same standard and have a high probability of failure. Any ECM you choose to partner with should not only have a vetted supplier network, but also a mitigation plan in place to avoid any counterfeit parts.

Does the ECM Have Certifications Relevant to Your Industry and Product?

Certifications are indicators that the ECM partner you have chosen consistently produces a high standard of work and is up to date on all the latest industry standards. In certain industries, maintaining a certification is necessary to meet the regulations of particular products. When considering the options for an ECM partner, look into the relevant certifications to ensure that your product will be manufactured by a company who understands the importance of compliance.

Cutting corners on any of these aspects may appear to save money initially, but it will typically cost you more in both time and money in the end. By choosing an ECM with the right qualifications, you can count on having a quality PCB in your product and can deliver that component without delay. Outsourcing your PCB manufacturing to the right partner can save your company both time and money, along with providing the assurance that your PCB will function exactly as intended. To learn more about our turnkey PCB assembly and manufacturing services, contact Levison Enterprises today.

Start Your Quote Now!