The Importance of Gerber Files in PCB & Electronic Manufacturing

Gerber files play an important role both as a translator and connector between electronic manufacturers and design engineers. With Gerber files, manufacturers can easily understand the design engineering concept, which enables them to provide you with reliable products, as well as ensuring an efficient and effective manufacturing process.

Gerber Files Communicate All the Design Details to the Manufacturer

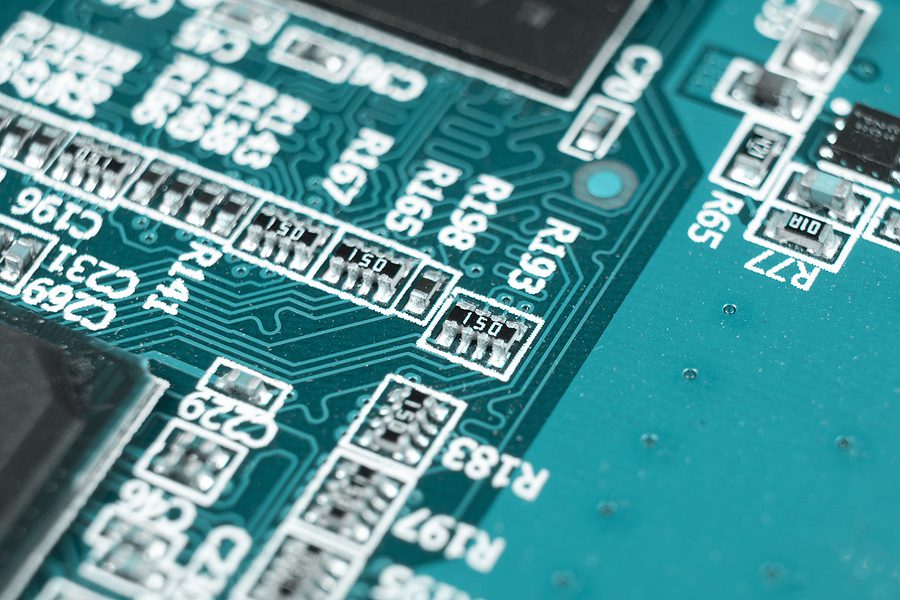

Gerber is an ASCII vector format used for PCB design and is therefore usually referred to as PCB Gerber files. This is an open-source format that is used for defining the PCB design specifications, which include all the design details. The PCB design process usually involves Electronic Design Automation (EDA) or Computer-Aided Design (CAD). The Gerber files are used to present the image standard input format of the design. These files aid tremendously in PCB manufacturing.

Provide Configuration Parameters Including Size, Shape, and Depth of PCB

Most Gerber files include configuration parameters referencing the size, shape, and depth of the PCB, including syntax that begins and ends with text blocks. Configuration parameters vary according to the type of Gerber file. These configuration parameters control every activity performed by the Gerber files.

Macro and Aperture Dimensions

Macros define rarely used geometrical figures and aperture defines the shape and size of the PCB board in a Gerber file. Logos, letters, and registration marks are all included here. In a CAD system, macros are AM parameters that are used to fill gaps between original features and specifications.

Drawing Commands

Gerber files have three drawing primitive commands that will define the thickness and geometrical shapes in a PCB design. These may be flashes, arcs, and lines. A “step and repeat” command will make it possible to draw complex shapes that may not have been possible without a Gerber file.

X/Y Coordinates

Gerber defines the X and Y coordinates of each geometric shape drawn as a placeholder. With these coordinates defined, PCB Gerber files act as PDFs for the electronic manufacturing industry, making them an extremely important format in PCB manufacturing.

Gerber Files Define Every Specification

When it comes to PCB manufacturing, every specification matters, and if you and the manufacturer are using different software, variations can occur that can delay your product. Gerber files define and clarify every image of the board, including the thickness of boards, locations of components and holes, and board layers. Gerber files maintain the precision needed to build the PCB correctly and will reduce the risk of defective boards. After designing the PCB, the manufacturer will need to be provided with all the files to maintain that precision.

PCB designs are getting complex, and the traditional tools such as vector photo plotter tools will no longer be enough. Compact designs are made up of multiple layers, and Gerber files can handle 20 layers and more. The files are time-convenient, allowing for more efficient production and time to market, and the information is documented and can be traced back easily.

Start Your Quote Now!Gerber file creation is a service that many turnkey electronic manufacturing providers will offer their clients along with manufacturing services, and it is well worth the investment. To talk about your next project with an experienced turnkey ECM, contact Levison Enterprises today. We’ve become an industry leader in PCB manufacturing with our wide array of industry knowledge, and our team is eager to help you create your next successful product.