How Prototyping Can Create Industry Leading Electronic Devices

New product introduction is the process of taking an idea and refining it into a producible product. Taking a project from the idea stage through to production can take time, and prototyping is a crucial step in bringing the concept through from design to manufacture. Without prototyping, the device has a much smaller chance of success.

Types of Prototypes

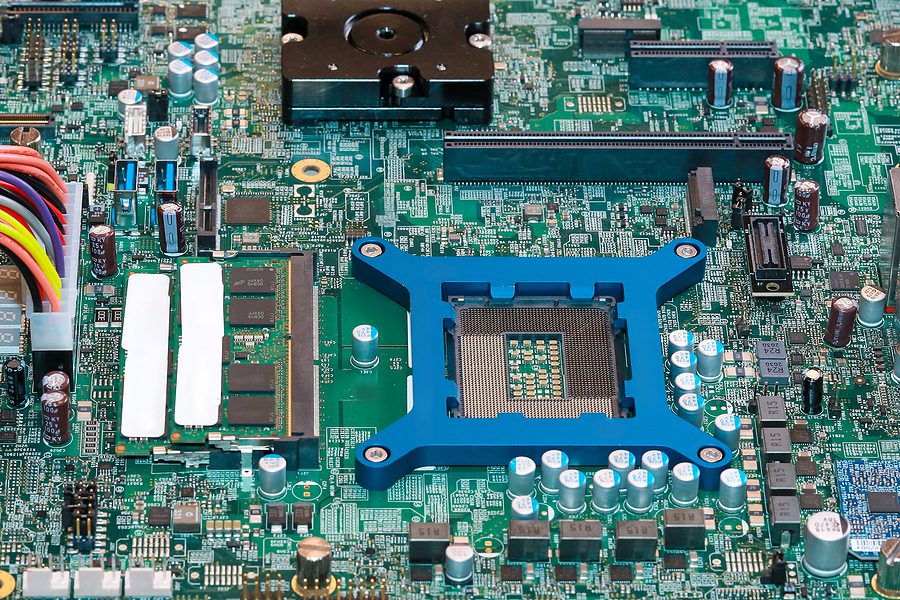

There are different types of prototypes, and the one you choose to work with depends on the needs of your project. A mockup is the first stage of prototyping and will not act as a functional unit. A design concept prototype will include some of the intended functionality of the product and can confirm the design and concept, but will not have the capability of a fully functional board. A working model is the most often used prototype in many industries. A working model prototype will perform as the final product will, and contains all of the expected functionality. While refinements can be made, it is a fully functional board. Once the prototype is made, design can be refined and finalized. The development of the prototype is essential to the success of the project.

Prototyping Avoids Risk

If you don’t use a prototype or work only from a mockup, there are many risks in the product development stage. You may find yourself sourcing parts that you can’t use or don’t fit together properly. Your design may not function as you want it to, and you may find that the product can’t be marketed because it won’t fit the right specifications. Having a product failure in the manufacturing stage, rather than the prototyping stage, is expensive and time consuming.

Prototyping Provides Proof of Concept

Until you see the device perform as you expect it to, you can’t be certain that your design is correct. Prototyping allows you to see the pieces together and confirms that the design performs as you want it to. A prototype allows you to see what happens when the design is assembled. From there, you can make adjustments without a large investment of time and money in manufacturing.

Prototyping is Critical for Regulation

Regulatory hurdles are present in most industries. Significant testing is needed for many designs to make it to market. Prototyping is the first step to get to the testing phase of production. If your product needs to clear regulations, you need to have a functional prototype before you begin the next phase of production.

Prototyping is Important for Design-for-Manufacturing

Designs don’t always work as you want them to. In some cases, a design may look and function well, but will create manufacturing issues. In the prototyping phase, it is easy to go back and work with the engineers onsite to refine the design and create one that will work best for manufacturing.

Prototyping Means an Efficient Build with a Turnkey ECM

If you partner with a turnkey ECM, design and prototyping are available as part of your project. With prototyping done by the engineers onsite, you can have an efficient and successful build. These engineers will have the experience and knowledge to take your design through the prototyping stage and develop the most efficient and cost-effective build.

Start Your Quote Now!Prototyping is a step that should not be skipped in the design and manufacturing process. You may have an initial investment, but you will ultimately save time and money, ending the process with a functional and manufacturable product. If you’re interested in learning more about our state-of-the-art facility and turnkey capabilities, including design services and prototyping, contact Levison Enterprises today.