5 Warning Signs Design Engineers Should Look For in an ECM Partnership

The right electronic contract manufacturer with the right team and the right tools will successfully serve all of your needs from prototype to production. After all, electronic contract manufacturing plays an important role in industries around the world. However, the relationship with your ECM can be a lot like any other relationship. When it’s good, it’s good, but when it is bad it is really BAD. Here are some warning signs that will make you pull off those ECM rose-colored glasses.

1. Doesn’t Have Quality Certifications

Any electronics manufacturer who is worth working with will have multiple ISO, governmental, and military certifications to show off. Certifications are indicators of a high-quality manufacturer. Certifications such as AS9100 and ISO 9001 demonstrate a high commitment to excellence. If your ECM can’t or won’t produce them, it may be time to start looking. It means they have either not put in the time and energy it takes to earn quality certifications, or they do not meet the standards and requirements of the certifying organizations.

2. Doesn’t Have Existing Vendor Relationships Or Vetted Sources for Parts

Can you trust your ECM’s supply chain? Does your ECM guarantee quality, cost, and delivery of parts that will go into your product? A simple customer-supplier relationship is not enough when it comes to electronic components. You want an ECM with a trusted supplier network. Plus, all part sources should be thoroughly vetted so only the highest quality parts and materials are used in your build. Settling for less can compromise your product and your bottom line.

3. No Communication

Communication is key in any relationship. A marriage is only successful if you talk. The same goes for your work with your ECM. If they are not willing to answer your questions or pick up the phone, they probably aren’t the right electronic contract manufacturer for you. You want a manufacturing partner that is responsive to your needs. You and your ECM must work together as a team to ensure the success of your project. They should be able to react quickly to design and production changes.

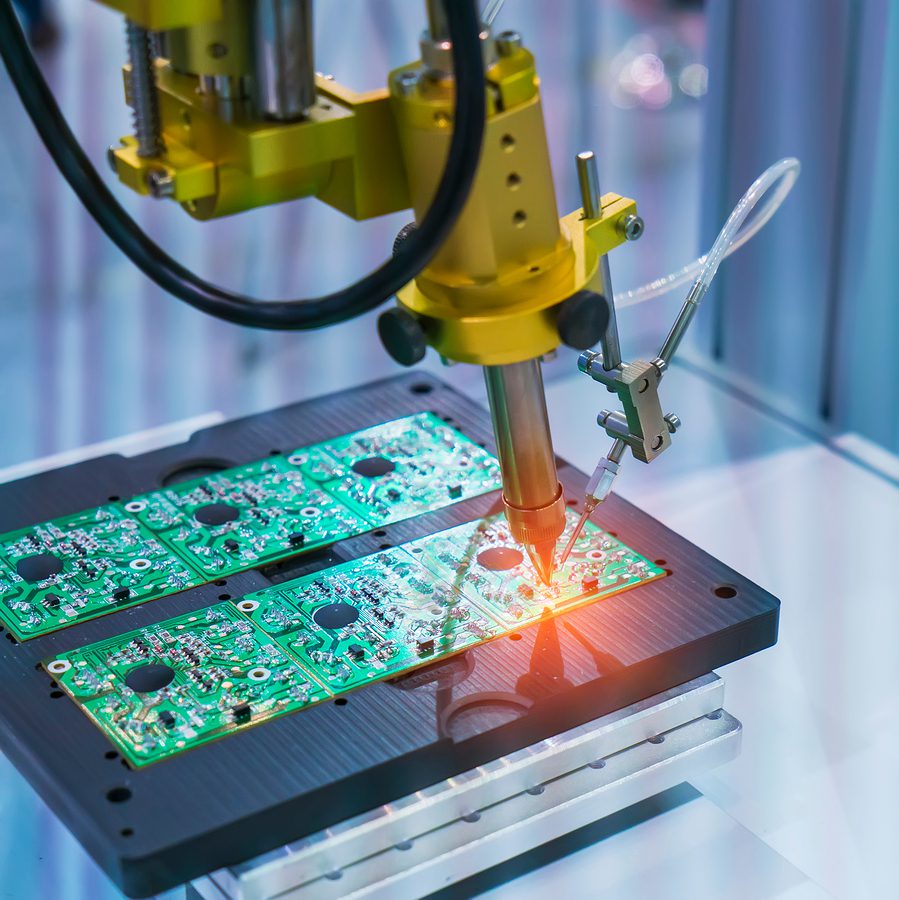

4. Unable to Prototype

Why are you working with one company for prototyping and another for the production run? Don’t use a company that only handles manufacturing if you want the best value from your electronic contract manufacturer. You’ll save time and money by hiring a company that does everything under one roof. It is worth it to work with an ECM who does prototyping in-house and can also handle your production run.

5. No Engineering on Staff

It is hard to believe there are electronic contract manufacturers who do not have engineers on staff, but it happens. Your engineers and your ECM’s engineers must work together to get a project from design to assembly. They work better together when they are under the same roof. Overall, on-site engineering will save you time and money.

Partnering with the right ECM can make or break your project. Levison Enterprises offers a wide array of solutions for your electronic manufacturing needs. We carry AS9100 and ISO 9001 certifications, and we are ready and able to tackle your project. Contact Levison today for a free quote.